Look under the hood of an automobile and what you see might overwhelm you. Simultaneously, dozens of parts -- each with a specific function and purpose, working in unison towards a common goal. In truth, there’s something marvelous about it! So, how do oil-free and reduced packaging initiatives apply?

The Marvel of Modern Engineering

Upon changing your wiper fluid or changing your oil, stop a moment and look at everything that’s happening.

None of us assume that engineering an automobile is simple, considering that the average car contains around 30,000 parts! Automobiles are puzzles with LOTS of different pieces and ensuring that these parts perform adequately is of the utmost importance.

The process of packaging, shipping and implementing these parts is a major undertaking.

Transit, Logistics & Corrosion

While most automakers will manufacture some of their car parts in-house, all and all, they also utilize suppliers. Accordingly, quality assurance is at the top of their list. However, producing all of an automobile’s innumerable components would be extremely costly and time-consuming. Hence, a logistical dilemma is born.

Manufacturing and shipping auto parts around the globe results in metal degradation issues. As a result, many auto parts are prone to oxidation, rust and other forms of corrosion. These degradation issues pose a threat regardless of geographical location (atmospheric pollutant gases and moisture are everywhere!). However, they certainly occur in some places more than others.

Sulfur gas emissions and pollution levels overseas are staggering. While in transit from supplier to auto manufacturer, parts inevitably succumb to these elements and begin to corrode. Inasmuch, this is costly, wasteful, and averse to the environment.

Dated Methods of Corrosion Protection

How do auto manufacturers go about solving corrosion issues? Unfortunately, many of them approach corrosion prevention with dated Volatile Corrosion Protection. Despite being wasteful, potentially harmful to the environment, and often ineffective -- these methods of corrosion protection are widely utilized out of convention.

Dip or Oil Coating

- Dip Coating auto parts works temporarily, but requires an extensive removal process.

- The oil adheres to the part's metal surface as a means of corrosion protection.

- Once the parts arrive on-site at the assembly plant, they undergo another dipping/cleaning process. Oil removal often uses chemicals that are expensive to dispose of.

- Many of these oils ARE NOT biodegradable.

- Dip Coating often renders plastics non-recyclable.

- 50 ML’s of oil per 1 Cubic Meter (m3) of plastic renders the plastic non-recyclable by European environmental law.

Volatile Corrosion Inhibitors (VCI's)

- VCI’s are a method of volatile corrosion protection.

- VCI materials work by off-gassing chemicals.

- VCI's around gaskets, natural rubber, polycarbonate or items considered as "swellables".

- Metals placed into bags/wraps that emit a vapor and coat the metal, ostensibly protecting it from corrosion.

- VCI’s have temperature and shelf life limitations that should be carefully reviewed. They're often times narrower than what automotive shipping demands.

- It is generally considered that these volatile protection systems need close proximity between the parts and the emitting material. The proximity is generally 6” or less, which makes bulk packaging difficult.

Oil-Free & Reduced Packaging Initiatives

In brief, Intercept Technology™ was created as an effective, volatile-free, re-usable and recyclable packaging option. Our corrosion prevention systems are used in a wide variety of industries – including automotive.

Intercept™ offers several options of oil-free protection, including packaging for engines, transmissions and other components during shipping or storage. Basically, this is done in an effort to remedy the problems caused by the anti-corrosion methods listed above.

Our packaging systems are used for short-term storage, as well as long-term. Approved by the German Automotive Industry, Intercept™ packaging is certified for storage up to 15 years. More impressively, we accomplish this feat oil-free!

Intercept Technology™ reduces the amount of plastics needed for shipping and reduces the amount of material entering landfills. This is possible with our usage of recyclable and re-usable bulk packaging and our elimination of oil coating and vapor barriers. Moreover, our Intercept Automotive Systems are MORE EFFECTIVE at preventing corrosion than the outdated methods listed above.

Intercept™ Automotive Packaging Systems

Method 1

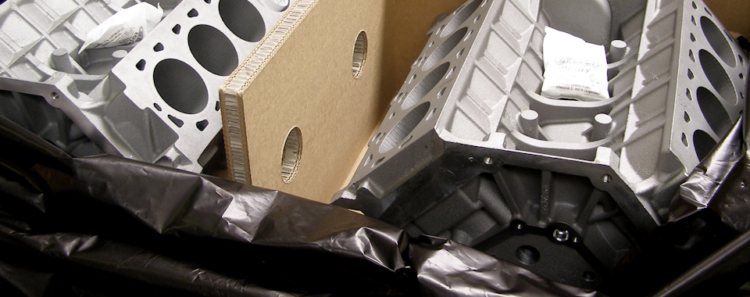

Oil-Free Packaging of Engine Blocks

- Individual bagging of engine blocks.

- Saves the need for other corrosion protection.

- No oils, emitters, VCI paper, VCI plastic, etc.

- Re-usable engine block bags.

Method 2

Dunnage Inserts for Trays

- Eliminates the need for bagging.

- Saves the need for other corrosion protection.

- No oils, emitters, VCI paper, VCI plastic, etc.

- Intercept volatile-free trays and inserts have been in service for years. Some trays have gone through over 1000 wash cycles with no decrease in effectiveness.

In summary, forward-thinking auto manufacturers are cutting down on costs and environmental impact by using sustainable, oil-free Intercept™ Technology packaging. Together, we're taking the auto manufacturing puzzle and solving it one piece at a time.