Intercept Technology now offers a 3D printable ribbon. Correspondingly, the world is demanding faster, better, and more immediate availability of custom products when the customer wants it. 3D printing is able to provide users the ability to build complex functional items quickly, efficiently, and on demand.

However, the functionality of 3D printing did not include products that were useful for anti-corrosion and/or ESD protection for components or parts in an assembly. EMI has changed that reality.

Intercept Technology Presents the Next Generation of Functional 3D Print

Innovative Versatility

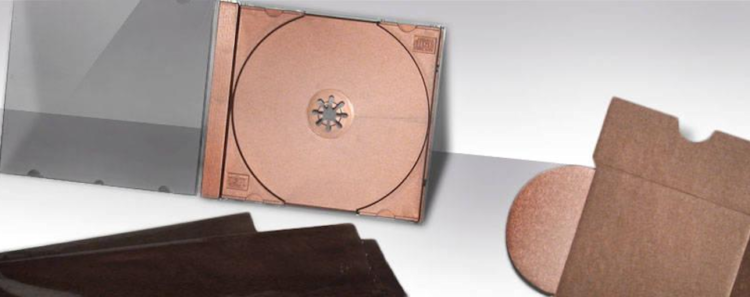

Intercept Technology, long term stable, oil free corrosion protection has developed a new 3D printable ribbon. Other traditional volatile based anti-corrosion technologies use volatiles and oils which cannot be put into a 3D spool. However, Intercept is a copper based polymer which is solid state and volatile free. Also, it is stable at the temperatures required to make the 3D spools (and stable at the 3D printing temperatures). For corrosion protection, spools are available in a PLA base. For corrosion protection with permanent ESD protection, spools are available in an ABS base polymer.

This is yet another extension of versatility where Intercept Technology in industrial and consumer markets is concerned. Its development originates at Engineered Materials, Inc. (EMI), an Illinois based corporation with offices and technicians around the world. The development allows for printing of complex parts and shapes for on board electronics, aviation, aerospace and other applications. Specifically, those which require corrosion and/or ESD protection for key components. The non-volatile nature of our anti-corrosion 3D print allows insertion into high end, extremely clean applications.

Intercept products are available worldwide, with production domestically and in Europe. The development ensued at the request of two diverse industries, one in the consumer electronics market, the other in high end aerospace. The common link was the need for long term, stable, non-volatile, clean corrosion protection on board with their product. In summary, this development compliments Intercept Technology injection molding and thermoformed parts and trays. Subsequently, it takes it to a new, easy to manage, easy to produce format.

For more information, please call us directly at (847) 821-8280, or send us an email.